How to automate sterile processing

As many as 20% of healthcare providers have already adopted IoT technologies to improve care -- according to the Gartner "Hype Cycle for Real-Time Health System Technologies, July 2020"

IoT in healthcare is foundational to digital business and, as such, will transform care delivery as it evolves and matures. Its projects will positively impact healthcare providers' ability to deliver care more efficiently and cost-effectively. Connected things will drive revenue and improve operational efficiency and asset utilization. -- Gartner

And, 50% of healthcare providers have already adopted RTLS systems for people and item locations.

RFID enables your medical equipment to tell you where it is. Surgio provides your team with a digital twin where you can plan, react, and increase patient safety.

Medical Tray Processing as IOT

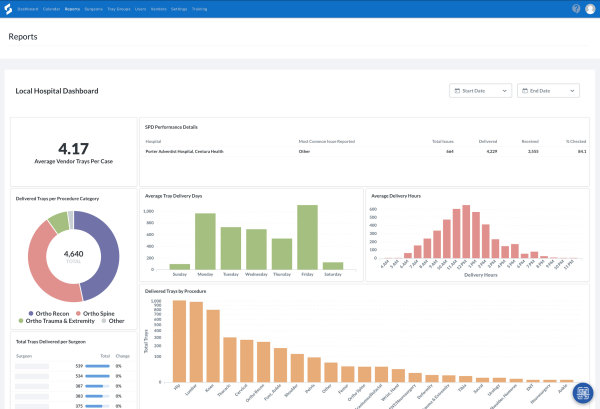

SimplyRFiD partnered with Surgio to modernize medical tray procurement and preparedness.

Surgio monitors all forms of hospital and vendor (loaner/consigned/owned) instrumentation and equipment throughout their lifecycle. By integrating with SimplyRFiD, Surgio takes its medically-certified workflow process for hospital tray management and adds visibility through RFID's automated tracking.

With medical trays, there are three primary issues:

- Availability: Scheduling tray delivery and confirming receipt of correct trays for a procedure.

- Sterilization: Improper or incomplete sterilization causes loss of life.

- Location: Misplaced or trays not in the right location create an average loss of 15 minutes per procedure.

Many paper systems or order-entry solutions exist to keep track of this, but they simply don't work. Sterile processing failures lead to infections with a 3% mortality rate and 3.3 Billion in associated costs according to ECRI.

Advent of the Digital Twin

Lofty words tossed around from six-figure consulting agencies -- but, in it's simplest form: A Digital Twin lets you play 'what if' on a physical world process.

Today, you have to manage a clipboard and checklist to see if a medical tray has been received and processed. Surgio is the digital twin of your paper process -- only it operates at super-speed and can remember thousands of tray combinations.

Adding in SimplyRFiD's RFID technology for real-time location tracking, you create your own IoT system that tracks and monitors your med tray workflow.

Surgio schedules and manages tray availability and sterilization status. SimplyRFiD tracks the tray location. Combined, these technologies save an estimated 15 minutes per procedure (HIMMS quote, Ku et al. 2011).

IoT and digital twins aren't just a future technology; it's here today. Using Surgio and SimplyRFiD for your medical trays, you can plan and forecast using technology vs. clipboards. Every medical item is internet-connected and can report on its status and location and proactively report errors before they happen.

THE PROCESS

Tagging

- RFID (Radio Frequency ID) tags that can withstand the autoclave process are attached to the med trays via a medically sterilizable stainless steel loop.

- Tags are associated to trays using the SurgioSPD workflow system.

These steps are typically done by the vendor when they arrive and check a tray into your hospital workflow. For permanent trays, this is all done at setup time.

Tip: Wrapping the tray does not prevent the RFID from reading. RFID will still update the tray location and will help locate mislabeled medical trays.

Auditing and updating

- SimplyRFiD fixed RFID readers are installed throughout the hospital SPD and Operating Room Core.

- When medical trays enter an area, the reader sends updates to your Surgio workflow system.

- Surgio updates the location of your medical trays. Location. State (Clean/Dirty). Where they are needed next.

Alarms

Further on that -- every tray is tracked for sterilization and monitored. If a compromised tray enters the OR Core, an alarm will go off, and alerts sent before a patient enters harms way.

Demonstration of Alarm in SPD